Needle roller bearings

Our needle roller bearings are bearings with cylindrical rollers that are small in diameter relative to their length. The modified roller/raceway profile prevents stress peaks to extend bearing service life.

Our supplies needle roller bearings in many different designs, series and in a wide range of sizes, which makes them appropriate for a wide variety of operating conditions and applications.

Inner rings as wear sleeves

Product types

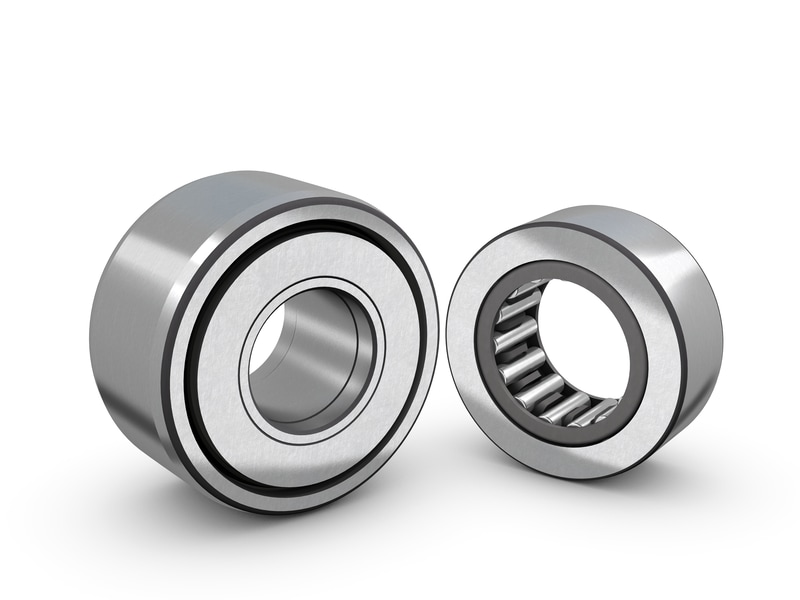

Needle roller and cage assemblies

SKF needle roller and cage assemblies are self-contained, ready-to-mount bearings. In applications where the shaft and housing bore can serve as raceways, the assemblies can be used to create bearing arrangements that require minimal radial space.

Drawn cup needle roller bearings

SKF drawn cup needle roller bearings have a deep drawn, thin-walled outer ring. Drawn cup needle roller bearings are typically used in applications where the housing bore cannot be used as a raceway for a needle roller and cage assembly, but where a very compact and economical bearing arrangement is required. These bearings are mounted with a tight interference fit in the housing. That enables a simple and economic design of the housing bore, as shoulders or snap rings are not required to locate the bearing axially.

The drawn cup of hardened steel and the needle roller and cage assembly of these bearings form a non-separable unit.

Needle roller bearings with machined rings

SKF needle roller bearings with machined rings are made of carbon chromium bearing steel. SKF supplies these bearings with or without flanges on the outer ring, in a wide range of series and sizes. SKF also supplies them with or without an inner ring.

Alignment needle roller bearings

SKF alignment needle roller bearings have an outer ring with a sphered (convex) outside surface. Two polymer seating rings with a sphered (concave) inside surface are encased in a drawn sheet steel sleeve and fitted over the outer ring.

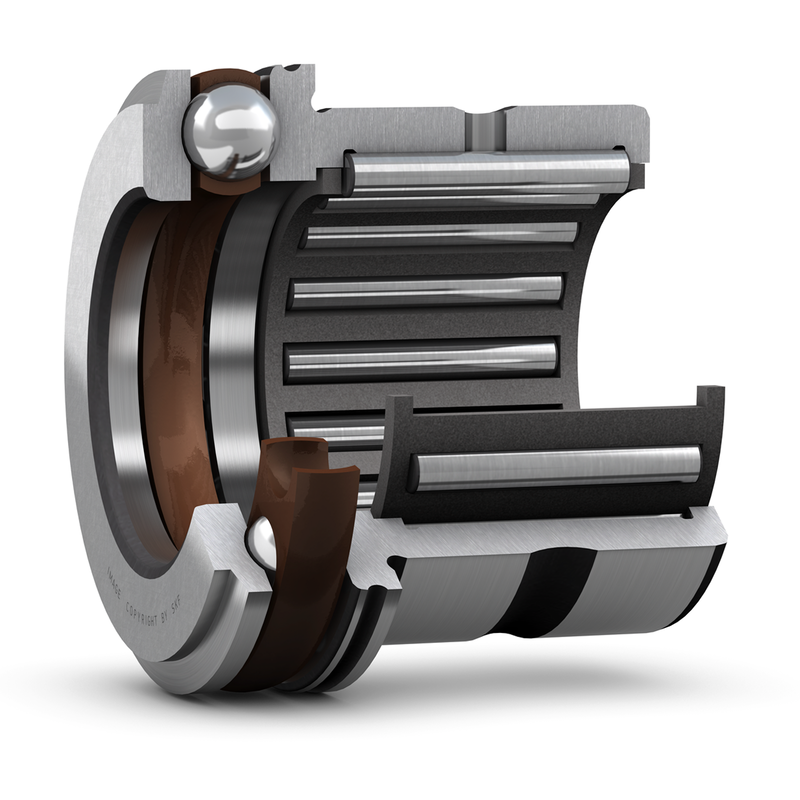

Combined needle roller bearings

SKF combined needle roller bearings consist of a radial needle roller bearing combined with a thrust bearing. They can accommodate both radial and axial loads. They are particularly suitable for applications where other types of locating bearing arrangements occupy too much space, or where the axial loads are too heavy, the speeds are too high, or the lubricant is inadequate for arrangements with simple thrust washers. SKF supplies combined needle roller bearings in three basic designs:

- Needle roller / angular contact ball bearings

- Needle roller / thrust ball bearings

- Needle roller / cylindrical roller thrust bearings

Relubrication intervals for the radial and thrust part of the bearing must be calculated separately. The shorter of the two intervals should be used. For additional information about lubrication, refer to Lubrication.

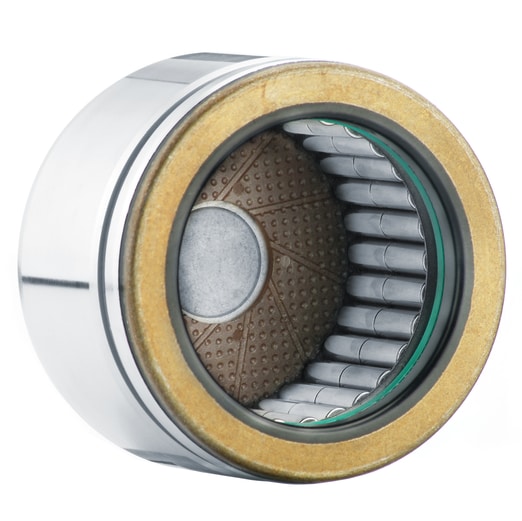

Universal joint bearings

SKF universal joint bearings are manufactured with cold forged or machined cup needle roller bearings, incorporating a closed end, and are for use in various types of application. They are used in the automotive industry, for joints in commercial vehicle propeller shafts, and also in other industries, for special applications.

SKF universal joint bearings (fig. 1) are available in various sizes and designs including:

- Designs that either require maintenance or are virtually maintenance-free

- Designs that are either open (without seals) or sealed

Needle roller bearing components

SKF supplies both inner rings for needle roller bearings and needle rollers as separate needle roller bearing components.

Inner rings are typically combined with needle roller and cage assemblies or drawn cup needle roller bearings in applications where the shaft cannot be hardened and ground.

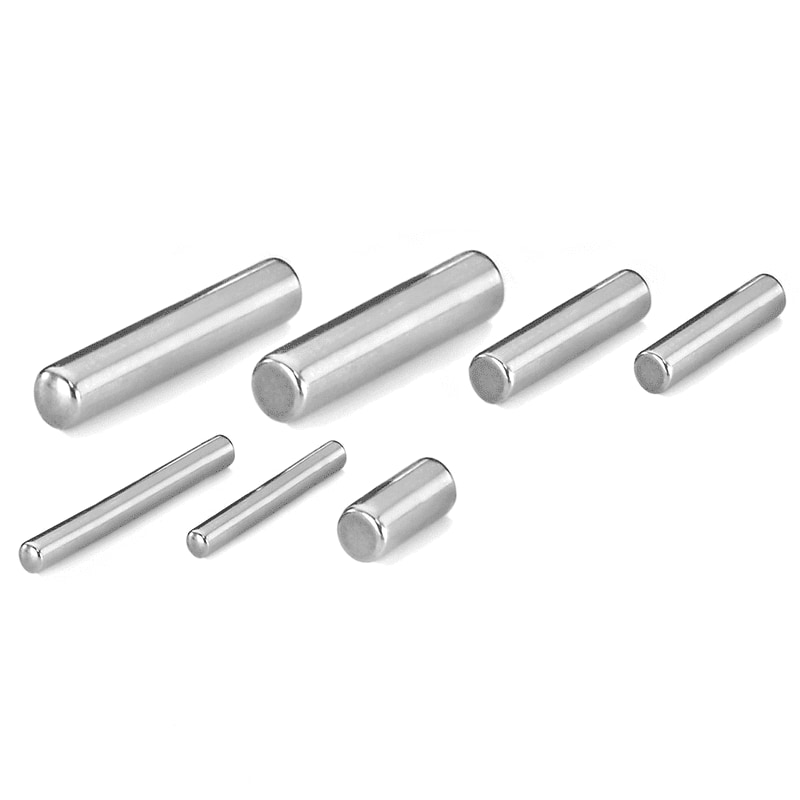

Needle rollers can be used to design full complement bearing arrangements for low-speed or oscillating applications. These compact bearing arrangements have a very high load carrying capacity when compared to bearings with a cage and are economical, provided the shaft and housing bore can serve as raceways (Raceways on shafts and in housings).

Product details

Needle rollers

- Are made of carbon chromium steel

- Have a hardness of 58 to 65 HRC

- Have a precision ground surface

For assistance in designing full complement bearing arrangements or to calculate performance data for these bearing arrangements, contact the SKF application engineering service.

Inner rings

Inner rings are available in two series:

- IR series

- With or without a lubrication hole

- With or without a machining allowance

- LR series

IR series inner rings

- Are the standard SKF inner rings for needle roller bearings (fig. 1)

- Are hardened and ground

- Have a precision ground raceway surface with a lead-in chamfer on both sides

The chamfers facilitate assembly and protect the seal lips from damage during the mounting process. - Are available in some sizes with a lubrication hole (designation suffix IS1, fig. 2)

Inner rings with additional lubrication holes are available on request. - Are available on request with a pre-ground raceway and a machining allowance (designation suffix VGS, table 1)

They can be finish ground after mounting on a shaft in applications where extremely tight geometrical tolerances are required.

LR series inner rings

- Are hardened, and the bore and raceway diameter are ground (fig. 3)

- Side faces are turned and the edges are smoothed

- Can be used to provide a cost-effective bearing arrangement for applications where the larger run-out and width tolerances are less important

Both inner ring series

- Are also available in different widths

- Permit greater axial displacement of the shaft, relative to the housing, when they are wider than standard

- Provide an excellent counterface for the lips of contact seals (fig. 4)

- Should be located on both sides to prevent axial movement (regardless of whether the ring has an interference or loose fit)

- One side can be located against a shoulder

- The other side can be located by either a snap ring, a distance ring or a nut

Other needle roller bearings

Needle roller thrust bearings

SKF needle roller thrust bearings are fitted with a form-stable cage to reliably retain and guide a large number of needle rollers. Needle roller thrust bearings provide a high degree of stiffness within a minimum axial space. In applications where the faces of adjacent machine components can serve as raceways, needle roller thrust bearings take up no more space than a conventional thrust washer.

Support rollers

SKF support rollers (yoke-type track rollers) are designed to run on all types of tracks and to be used in cam drives, conveyor systems, etc.. They are based on needle (fig. 1) or cylindrical (fig. 2) roller bearings. SKF supplies them ready-to-mount. They are available in several designs and variants:

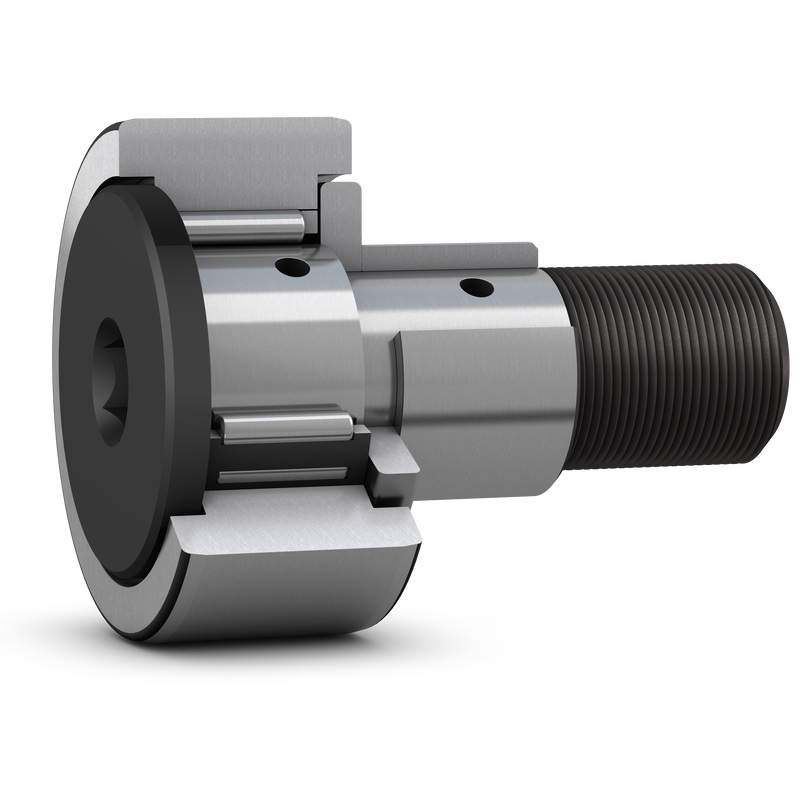

Cam followers

SKF cam followers (stud-type track rollers) are designed to run on all types of tracks and to be used in cam drives, conveyor systems, etc. They are based on either needle (fig. 1) or cylindrical (fig. 2) roller bearings. Instead of an inner ring, they have a threaded solid stud (pin). SKF supplies them ready-to-mount. They are available in several designs and variants:

- With (fig. 1) or without (fig. 2) a cage

- With different stud designs:

- With several sealing solutions

- With the outer ring running surface profile:

- Crowned as standard

- Cylindrical (flat)

In contrast to ball and roller bearings, where the bearing size refers to the bore diameter d, for cam followers the size refers to their outside diameter D.