Spherical roller bearings

Dealing with very heavy radial and axial loads in applications prone to misalignment or shaft deflections? Meet the challenge with spherical roller bearings, whose high load carrying capacity and ability to accommodate misalignment help you obtain low maintenance costs and long bearing service life. SKF invented this bearing type in 1919 and our range is the widest in the industry today – both open and sealed. Our assortment includes spherical roller bearings designed for many applications, including wind turbine main shafts, continuous casters, vibratory applications and high-speed applications, as well as bearings with Solid Oil, split bearings, SKF ConCentra roller bearing units, and, for the harshest operating environments, our SKF three-barrier solution.

Sealed SKF Explorer spherical roller bearings

Barrier 1

Barrier 2

Barrier 3

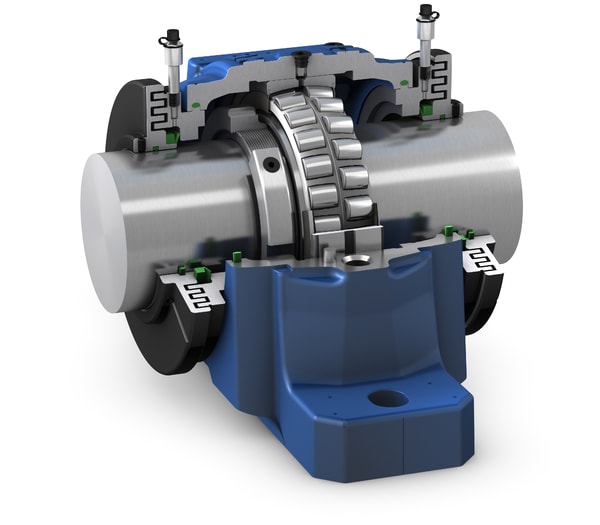

SKF Three-barrier solution

A specialized solution for highly contaminated environments: three barriers protect the bearing from contaminants – leading to extended bearing service life.

Increase conveyor uptime with three times the bearing service life

In mining and cement and aggregate operations, conveyor pulleys with open bearings live a tough life, coping with heavy loads while exposed to dirt and high-pressure washdowns. Ingress of dirt and loss of grease lead to insufficient bearing lubrication and indentations in the bearing raceways. The result is frequent conveyor breakdowns and weekly re-greasing. In eight out of ten mining plants, conveyor availability is less than 87%.

The upgraded SKF Three-barrier solution has an average lifetime three times longer than an open bearing. The result is fewer conveyor pulley bearing breakdowns and longer maintenance intervals – delivering up to 92% availability. This allows for planned maintenance of conveyor pullies to be timed with lagging replacement. The upgraded SKF Three-barrier solution also means re-greasing is needed only twice a year instead of once a week, saving up to 90% of the time and cost of greasing (up to 99.9% if not purged). It also delivers increased safety for maintenance workers.

- 3 x longer MTBF

- Up to 92% conveyor uptime

- Up to 90% less grease used

- Up to 99.9% less grease if not purged

- Reduced maintenance

- Increased safety

Bearing remanufacturing

Replacing industrial bearings can be expensive and energy-consuming. Bearing remanufacturing offers a cheaper, more environmentally sustainable option. We use a combination of reused, repaired and new parts to rebuild your bearing to the specifications of the original manufactured product.